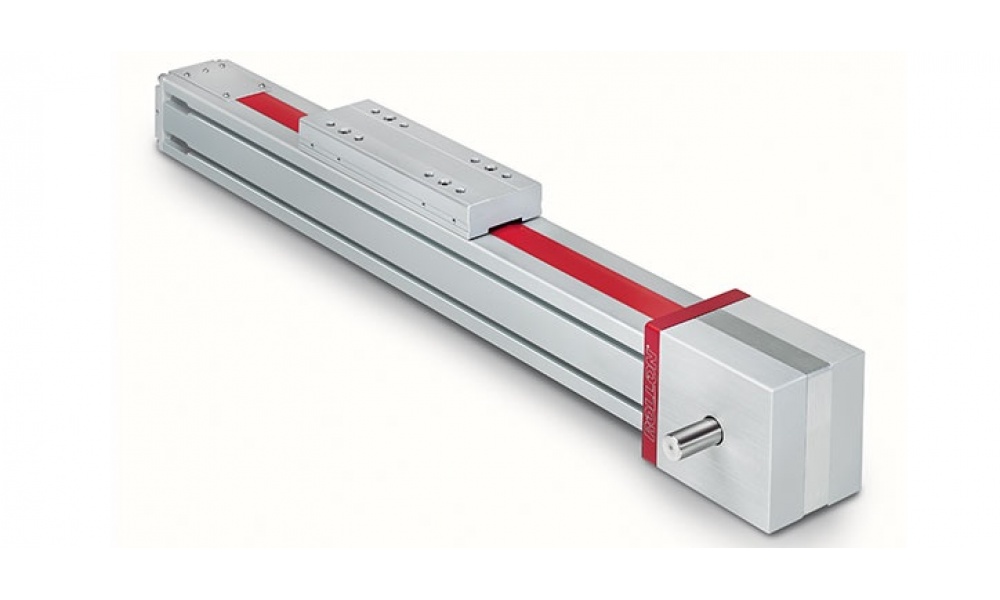

The CLEAN ROOM SYSTEM units are linear actuators with belt driven transmission and are specifically designed for Clean Room applications.

The system prevents particles from being discharged in the environment where the linear unit is located. This has been achieved by using a special straight seal that closes the horizontal opening where the slider moves, as well as by the operation of a 0.8 vacuum pump connected to 2 vacuum pipes located inside the drive head and the idle head.

The system allows vacuum to be generated inside the unit so that any particles released when the system is operating are sucked towards the air filtration areas. Clean Room System linear actuators components are all made of stainless steel or undergo special treatments ensuring a low particle release. The lubricants of all bearings and linear rails are special lubricants designed for use in CLEAN ROOMS or in VACUUM environments.

If the system is used in dirty environments, the CLEAN ROOM SYSTEM linear units can be pressurized to 0.8 bar to prevent any outside particles from negatively affecting its smooth operation.

.png)

.png?width=500&name=clean-room-2-(500x333).png)