Would you like to Tecline linear actuators?

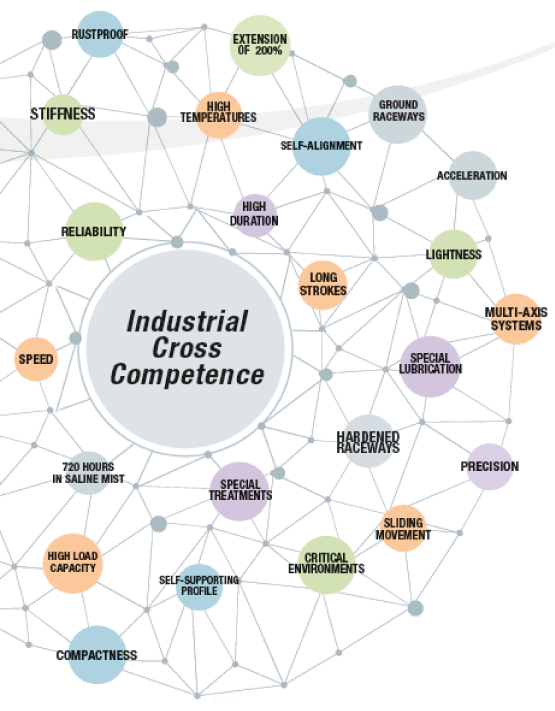

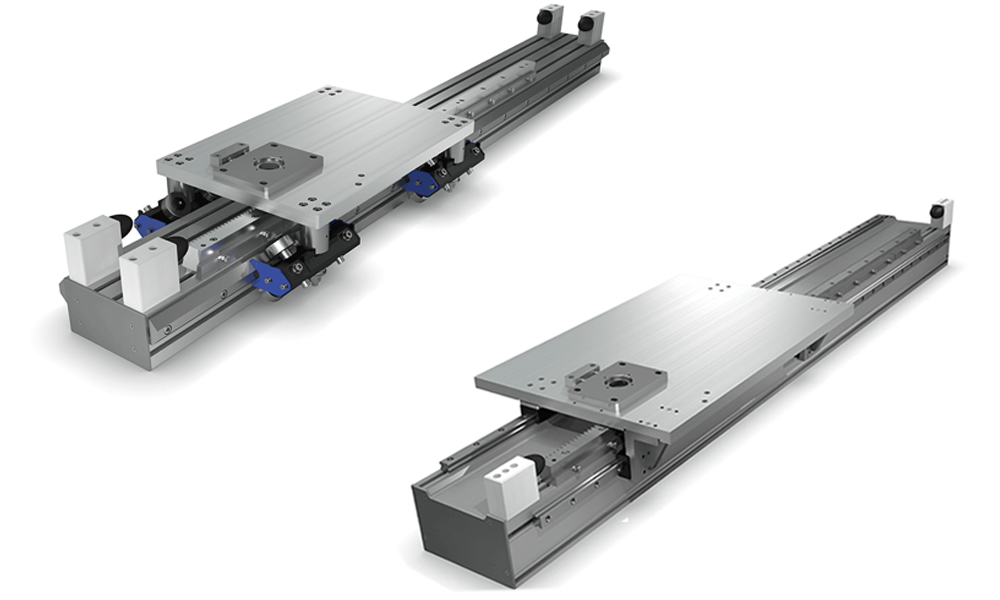

Tecline linear actuators are synonymous with:

- High loading capacity

- Excellent reliability in dirty environments

- Wide range of sizes for aluminum profiles up to 360 mm

- Ideal for extra long strokes thanks to rack and pinion transmission

These are linear axles with rack and pinion transmission for long stroke ideal in the following fields of application:

- Robotics

- Packaging and Logistics

- Industrial machinery

Fill out the form to get more information and understand how to make the most of Tecline based on your application needs.

Let us help you focus on your core competencies. Leave your details: we'll get back to you!

.png?width=500&name=tecline-(500x333).png)

.png?width=500&name=tecline-2-(500x333).png)