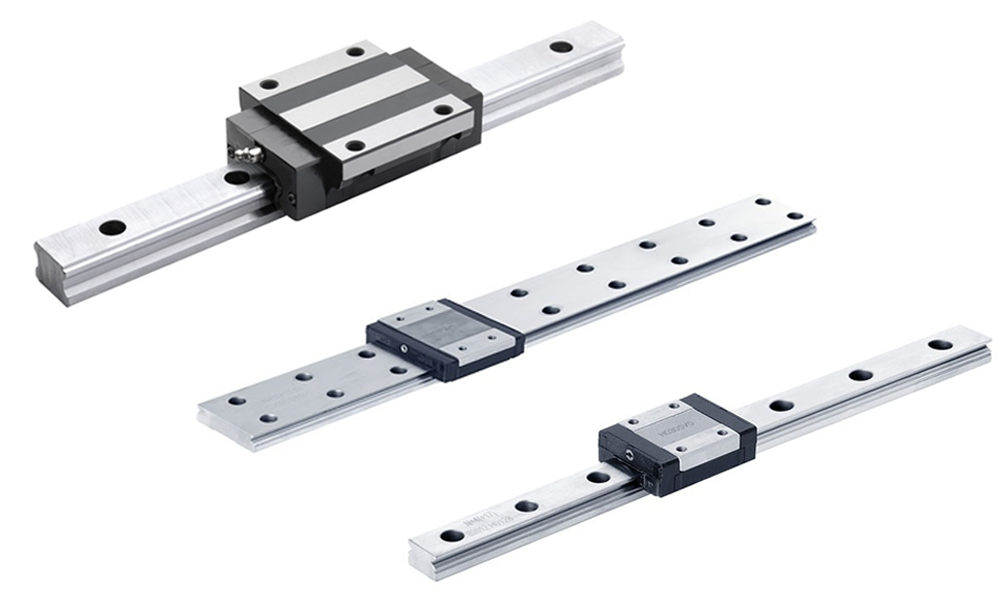

High load capacity linear recirculating ball bearing rail guide

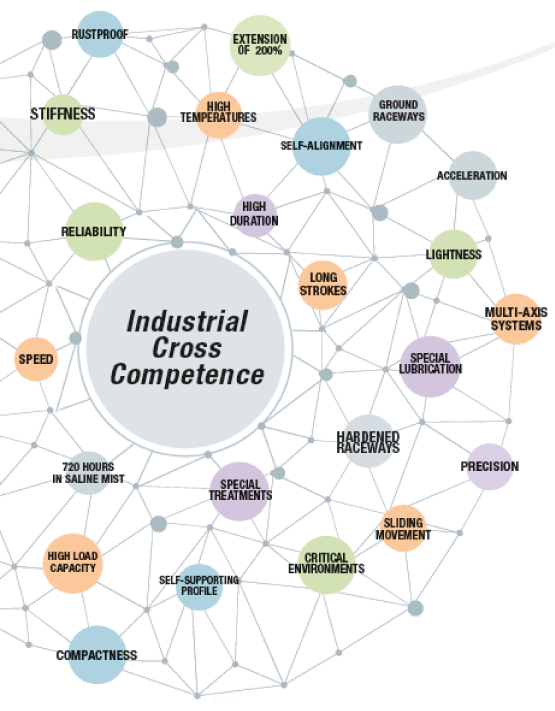

Mono Rail is the high load capacity recirculating ball linear rail that features a built-in grease system in the sliders and hardened and hardened ground raceways:

offers the industrial designer precision, robustness and carving capability for any application requiring high precision.

.png)

.png?width=500&name=mono-rail-2-(500x333).png)