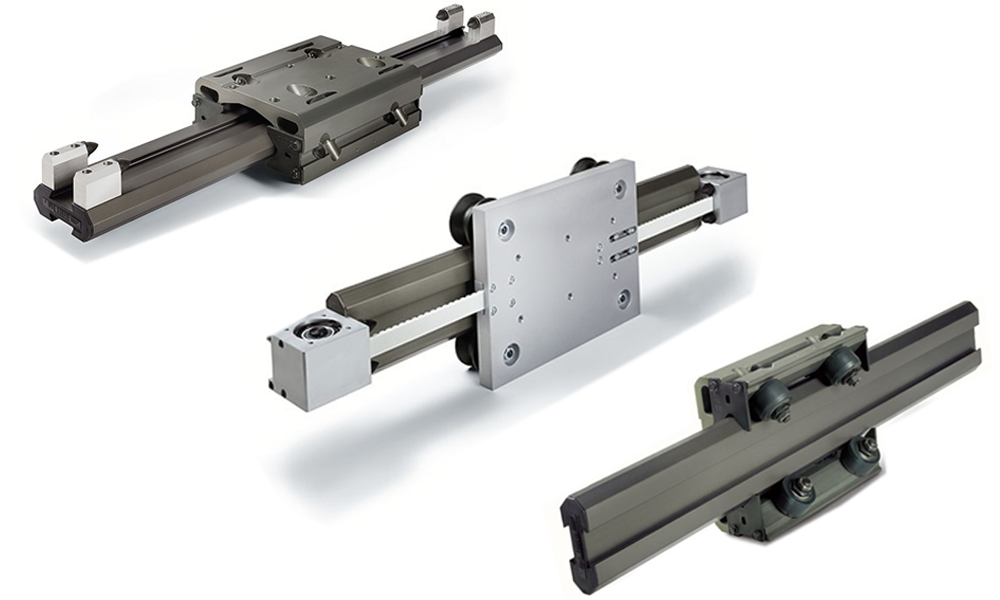

Self-supporting and self-aligning linear rail in die-cast aluminum.

Speedy Rail is the special rail with wheels covered in plastic compound and die-cast aluminum profiles with deep hard anodic surface treatment:

offers the industrial designer exceptionally high dynamism, great load capacity, maintenance and lubrication free, total reliability even in dirty environments and unique silent movement.

.png)

.png?width=500&name=speedy-2-(500x333).png)